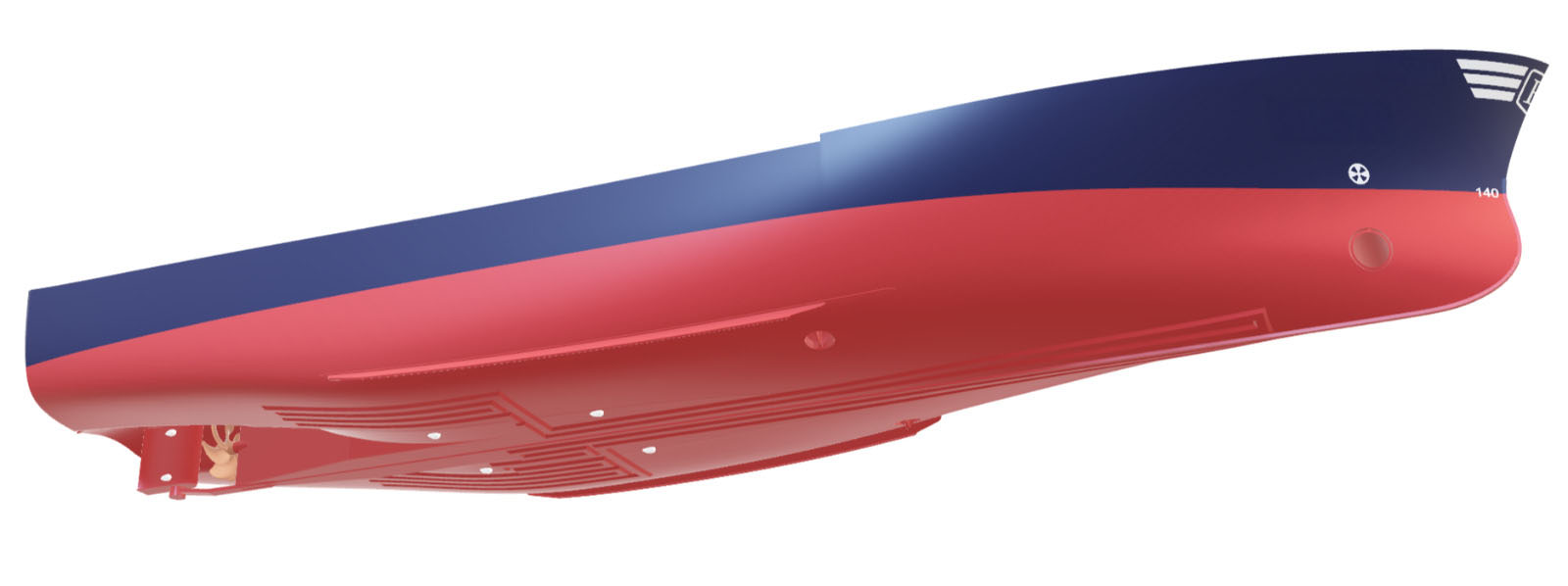

CFD-driven optimization for a 20-meter Fishing Cutter

The Challenge:

Poor Steering and Cavitation

Our client approached us with a clear set of issues:

- The cutter experienced unstable steering, both under manual control and autopilot.

- Excessive cavitation at the rudder caused significant wear and tear.

- There was a desire to improve the vessel’s speed if possible.

The steering instability and cavitation were not just inconvenient; they affected operational efficiency, safety, and long-term maintenance costs.

Our approach:

Data-driven analysis and simulation

Marimecs began by conducting detailed measurements during sea trials. These real-world insights provided a baseline for our CFD analyses.

Using advanced simulation techniques, we mapped the complex interactions between the hull, rudder, and propeller flow. The CFD studies revealed the core issue: the rudder’s shape and position were creating excessive turbulence and side forces, leading to instability and cavitation.

CFD optimization:

The key improvements

Through multiple iterations of CFD simulations, Marimecs engineered a comprehensive solution — without relocating the rudder’s position.

Key enhancements included:

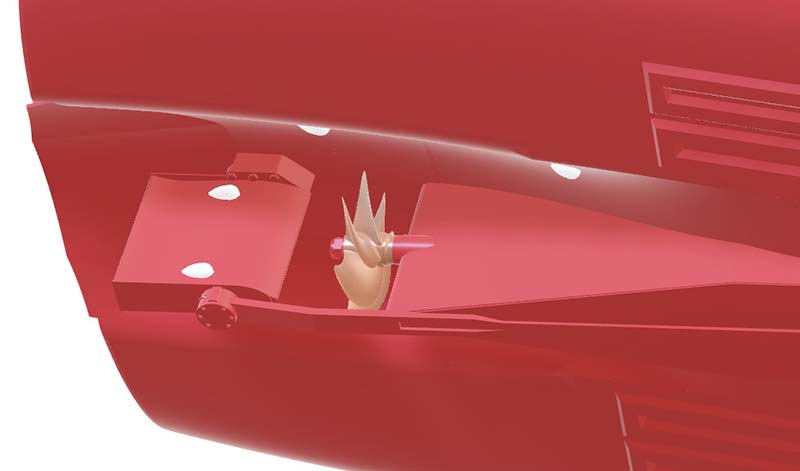

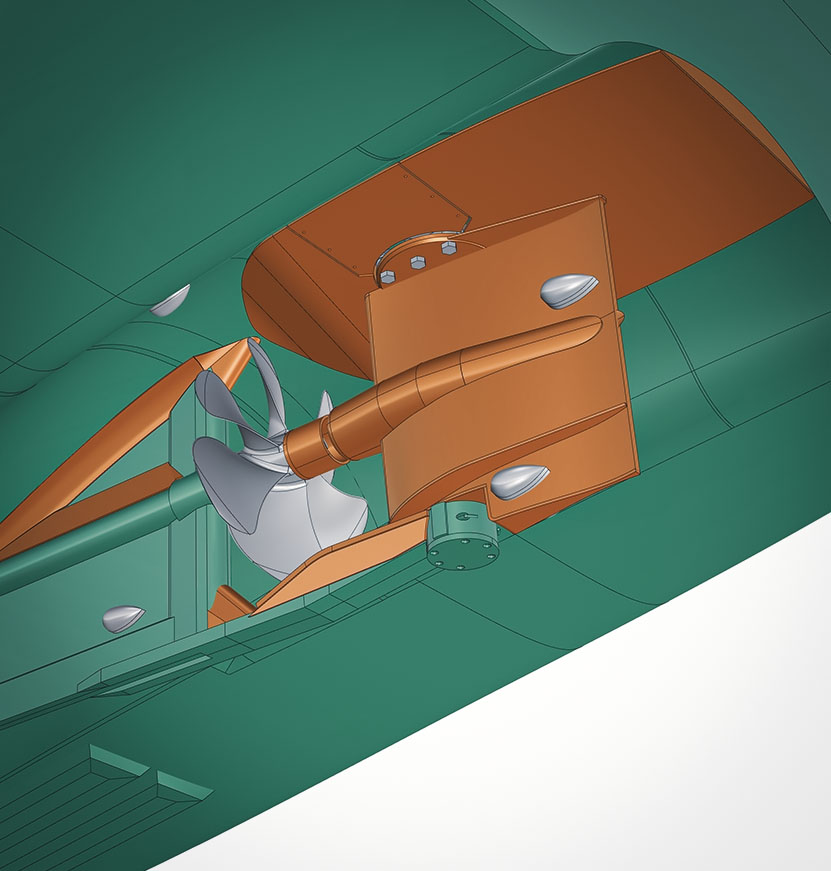

Asymmetrical rudder design

The rudder’s leading edge was reshaped asymmetrically, aligning it with the skewed propeller wash both above and below. This minimized crossflow forces and generated a subtle forward lift, slightly reducing drag.

Optimized rudder profile

Propeller hub extension and bulb

A hub extension was added, coupled with a central “bulb” on the rudder. This modification effectively balanced the transverse forces on the vessel and reduced side forces on the rudder to levels comparable with hull flow alone.

Marimecs new rudder design.

Asymmetrical rudder profile

Visual proof:

Before and after CFD results

We will illustrate this transformation with CFD visuals showcasing the flow dynamics before and after our interventions. These images will highlight:

- Unstable flow patterns and cavitation hotspots in the original design.

- Streamlined flow with reduced turbulence and minimized cavitation post-optimization.

- Pressure fields and flow patterns that reveal how the modifications improved performance.

The results:

Measurable improvements at sea

Sea trials following the modifications confirmed the effectiveness of Marimecs solutions. The outcomes were impressive:

Speed increase with same rpm as baseline

- 1407 rpm 11,8%

- 1503 rpm 13,5%

- 1600 rpm 11,5%

- 1790 rpm 6,6%

The cutter achieved a notable speed increase:

- At 1503 RPM, the vessel gained nearly 2 km/h compared to the baseline.

- Top speed reached 18.7 km/h in 7.3 m water depth, an increase of 1 km/h over the previous maximum at 3 m depth.

Fuel savings at same speed as baseline

- 13,6 km/h 48,7%

- 14,1 km/h 48,8%

- 14,8 km/h 46,2%

- 16,6 km/h 28,8%

Fuel consumption halved.

At 1100–1350 RPM, fuel consumption was reduced by almost 50%. Approximately half of this gain resulted from hydrodynamic improvements (rudder and hull), with the remainder from improved trim.

Enhanced steering

Trim Optimization

Conclusion

Ready to optimize your fleet?

If you’re seeking a partner who combines simulation tools with deep hydrodynamic expertise, contact Marimecs. Let’s explore how we can elevate your vessel’s performance through innovative design and optimization.